56

|

SPRING 2014

I

ncidents involving bad breathing gas — be it

air, nitrox, trimix or another mixture — are

rare, yet they do occur. Health effects on divers

vary depending on the contaminant breathed.

Among the most severe symptoms of breathing

contaminated gas are impaired judgment and loss of

consciousness, both of which may be deadly underwater.

Sources of contamination include hydrocarbons

from compressor lubricants, carbon monoxide (CO)

from engine exhaust (or overheated compressor oil)

and impurities from the surrounding environment such

as methane and carbon dioxide (CO

2

). Dust particles

in breathing gas can also be hazardous, potentially

impairing respiratory function or damaging diving

equipment. Excessive moisture can cause corrosion

in scuba cylinders and other dive gear and may cause

regulators to freeze due to adiabatic cooling (heat loss

subsequent to increased gas volume).

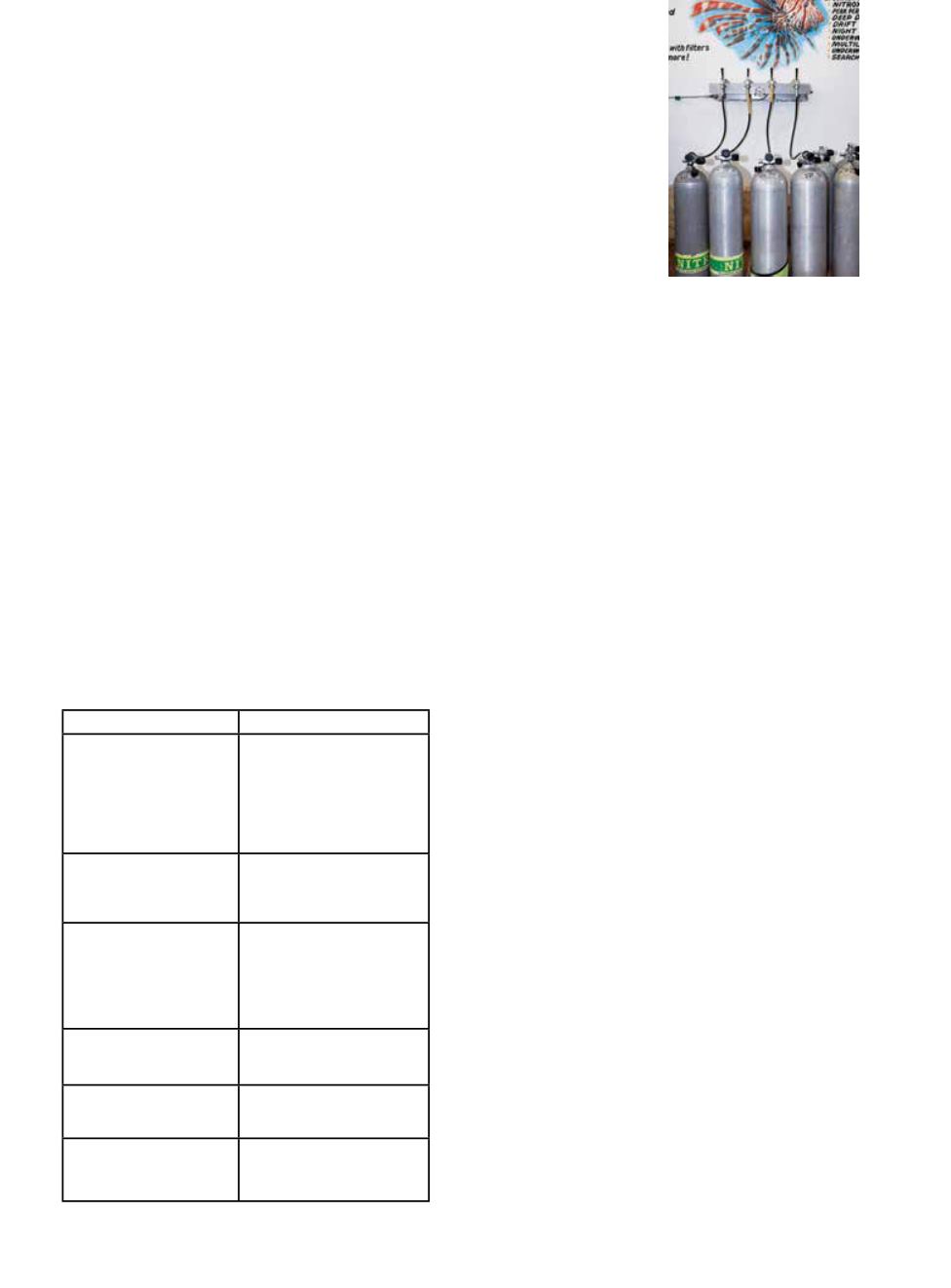

Contaminant

Signs and Symptoms

Carbon monoxide (CO)

Headache, dizziness,

weakness, nausea,

vomiting, shortness of

breath, impaired judgment,

confusion, unconsciousness,

potential death

Carbon dioxide (CO

2

)

Hyperventilation, dizziness,

confusion, unconsciousness

Volatile hydrocarbons

Fatigue, headache, confusion,

impaired judgment, numb-

ness, cardiac arrhythmias,

unconsciousness

Oil (condensed)

Headache, nausea, impaired

respiratory function

Dust (particles)

Impaired respiratory

function

Methane

Asphyxia due to dilution

hypoxia

Recommendations for Compressor Operators

Compressor operators can help prevent gas

contamination and mitigate the risk of dive accidents

in several ways.

Attentive compressor maintenance. Proper

compressor maintenance helps ensure breathing-gas

quality as well as extends the life of the compressor.

Breathing-gas contamination is less likely in well-

maintained and properly functioning compressors.

If maintenance is neglected and the compressor

overheats, the lubricating oil may break down and

produce CO and other noxious byproducts.

Effective procedures. A fill checklist can help ensure

safety procedures are remembered when cylinders

are filled. Before starting to fill tanks, the operator

should inspect the compressor’s filters for damage

and note the presence of contaminants such as

cigarette smoke, paint fumes or engine exhaust near

the intake. If the operator notes any chemical or oily

odors after filling has started, he should shut down the

compressor immediately. Other useful strategies for

reducing the risk of gas contamination include keeping

records of air fills and maintenance, ensuring operator

qualifications are up to date, using proper oil and

filters, and maintaining a clean and organized tank-

filling room.

Air-quality testing. As a diver descends and

ambient pressure increases, the amount of gaseous

contaminants breathed also increases. This explains

why a contaminated gas that is not toxic at the

surface may be at depth. Breathing gas must be

tested for a variety of contaminants both regularly

and continuously to ensure compliance with diving-

adjusted contaminant levels.

Compliance with breathing-gas quality standards

is not strictly enforced, and most of the responsibility

for testing lies with the operator. Several methods

of testing are available to compressor operators,

and they vary in price and complexity. Continuous

CO-monitoring devices include electrochemical

sensors with color indicators. Devices that

continuously monitor moisture level are also available.

B y B r i t t a n y T r o u t

RESEARCH, EDUCATION & MEDICINE

//

S A F E T Y 1 0 1

Preventing Breathing-

Gas Contamination

STEPHEN FRINK