GEAR CARE GUIDELINES

As divers, we’re all familiar with the demands of traveling with dive gear. Luckily, routine maintenance

and careful storage of gear can not only make your diving safer, but it can make your trip planning

easier. The following guidelines will help you make sure your gear is ready to go when you are:

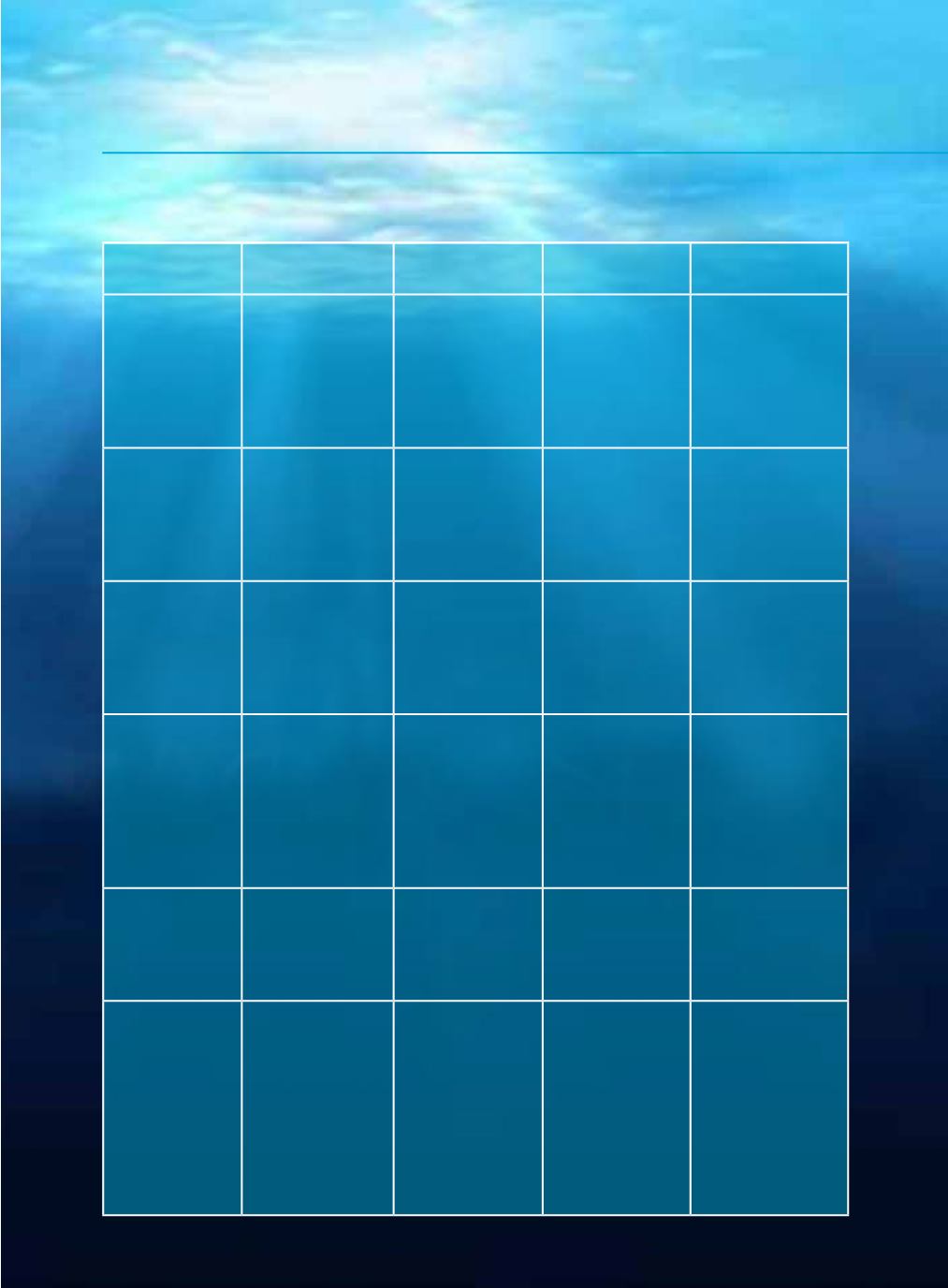

Item(s)

Before you Dive After you Dive

Storage

Professional

servicing

Mask, snorkel

and fins

Keep well

organized to

minimize the risk

of their being

kicked, stepped

on or tripped over.

Rinse and dry

well.

Pack and store

carefully so they’re

not crushed by

heavier gear.

Not applicable.

BC/BCD

Test before you

dive.

Rinse the outside

and flush the

bladder with fresh

water. Hang to dry.

After drying,

partially inflate

jacket for storage.

Have professionally

inspected annually;

remember the low

pressure hose and

dump valve.

Regulator

Test function as

soon as you set up

your gear.

Rinse and clean

while still connect-

ed to cylinder and

pressurized. Leave

out to dry.

Keep dust cap

in place and

secured. Store in

a regulator bag.

Service at least

once a year.

Wetsuit, boots,

gloves and hood

If necessary,

lubricate zippers.

Rinse, turn inside

out, and hang to

dry. If wetsuit has

an unpleasant

odor, use wetsuit

shampoo in

postdive rinse.

Store in the shade,

as neoprene is

susceptible to UV

damage.

Not applicable.

Dive computer

Check battery

icon.

Rinse and dry.

Store in a dry,

cool, ventilated

area.

Service every one

to two years, or per

the manufacturer’s

recommendation.

Cylinder

Handle with

extreme care,

as a pressurized

cylinder presents

a risk of explosion.

Secure tightly for

transportation.

Rinse thoroughly

and let dry.

Regularly remove

tank boot to

prevent a buildup

of salt and debris.

Never drain

completely of gas.

Reduce pressure

to the lowest

reading on the

pressure gauge.

Keep a clean,

dry dust cap on

cylinder valve.

Make a visual

inspection once a

year.

Perform a

hydrostatic test

every five years.